Hello;

I am Théo (Abbas) HAMADE.

R&D engineer with a PhD specializing in medical devices & Mechatronics.

R&D Engineer

I used to involve in multidisciplinary projects. I am actively engaged in learning about and solving meaningful engineering problems.

Software Used:

CCM+

ANSYS FLUENT

SOLIDWORKS

COMSOL

LABVIEW

Developer

I like to code things from scratch, and enjoy bringing ideas from life to simulation

Dev Tools:

MATLAB

C/C++

LATEX

PYTHON

FORTRAN

WORDPRESS

Scientist

I have been always fascinated with technology and the various ways it can impact our lives. I love machine learning. I love it also because it has a humble approach toward nature, it learns from nature.

Software Used:

Jupyter

My Work

2024-present

Paris-France

R&D Engineer

- Conducted a benchmark study on human brain flow dynamics.

- Improved and optimized algorithms and software through targeted enhancements.

- Developed models to simulate physical phenomena in pulsatile flow conditions.

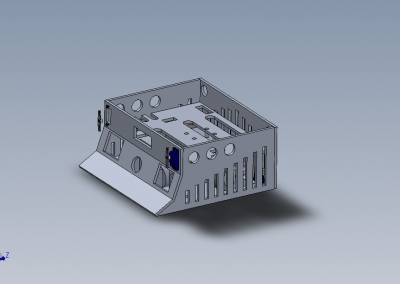

- Designed and built an acquisition box for data collection.

-

- Tools: Git, Python, Matlab, Slicer3D, ROS.

2022-2024

Velizy-France

R&D software Engineer

- Led MIL bench activities and improved HIL bench modeling capabilities.

- Performed numerical simulations of the cardiovascular system, including

back-to-back testing procedures. - Conducted an analysis and characterization study on diverse prosthesis subjects.

- Software : IBM Doors, IBM Synergy, Teamcenter, Matlab, Simulink …

2019-2022

Ecouen-France

PhD Candidate

- Developed a generic algorithm for predicting flow behavior.

- Developed a software to optimize perfusion lines in premature infants,

integrating medication concentration monitoring. - Conducted simulations to analyze fluid flow within infusion lines.

Designed and implemented controller systems for a prototype. - Conducted studies and modeling in fluid mechanics and control systems.

- Designed and implemented the control system for a novel prototype,

resulting in a filed patent.

2019

Jouy-en-Josas-France

Energy & Mechanical Simulation Intern

- Performed numerical simulations of hydrogen behavior.

- Conducted thermodynamic and thermal analyses of hydrogen behavior

- Study of the thermodynamic variables in cryogenic tanks

- Design & Sizing of cryogenic tanks

- Creation of a database of the different hydrogen vehicles in the world

EDUCATION

2014-2019

Bachelor in Engineering

Lebanese University

Relevant courses:

- Thermodynamics/Heat Transfer

- Turbomachinery/Energy Production

- Heat Engines/HVAC

- Mechanics of fluids/Gaz Dynamics

- Kinematics & Dynamics of machinery

- Electrical Machines

- Automatic Control

2018-2019

Master Degree -M2-

Sorbonne University

Relevant courses:

- The basis of Energetic Efficiency

- Numerical simulation for energy engineering

- Reactive systems, turbulence, and transfers, application to terrestrial and aircraft propulsion

- Aero-acoustic and energetic of aeronautical engines

2019-2022

PhD.

UPHF

Domains Involved:

- Hydrodynamics

- Control & Automation

- Fluid Mechanics

- Programming

- Implementing codes

- Hardware/Code Interface

My Recents Simulations

- Combustion Engine

- Turbo Compressor

- HVAC Design for a House

- Rocket Combustion Chamber

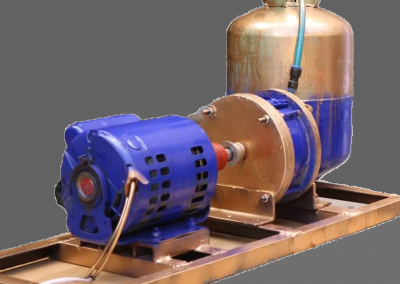

- Bucket & Extravador

The internal combustion engine is omnipresent in our daily life, it is the machine that has generated the most interest over the past two centuries. It still does now the subject of extensive studies in order to improve its performance and especially to regulate emissions pollutants.

In this project, we are interested in the type of controlled ignition based on the one-dimensional concept.

The physical and thermodynamic equations will be stated and then translated as an algorithm on Matlab in order to perform the simulation. In addition, each submodel will be validated and followed by interpretation.

A fully Calculation of heating, cooling loads, manually and on “Design-Builder”, for a modern house.

A Dimensioning of pipes, and sizing of ducts to meet the necessary loads.

The goal is mainly concerned with the turbulence in the systems reagents and its role in improving the combustion phase up to the optimization of the conditions in the reactor towards achieving maximum propulsion of an aircraft.

In this simulation, an aeronautical combustion chamber was chosen from the TAPS configuration (TAPS-M & TAPS-K)

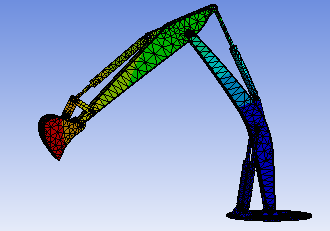

The object of this project is to make a finite element model of a hydraulic arm, & to study the deformation, the stress, the maximum forces applied on it, and the dynamics of the system.